Mold Temperature Machine Design

Customer: Guangdong Wensui Intelligent Equipment Co., Ltd

Year: 2022

Our roles: Industrial Design | Product Strategy | Appearance Design | Structural Design | Prototype Model

With the progress of the times and the development of technology, human living standards have been greatly improved, and machinery and equipment have become increasingly intelligent and widely used in various fields, such as mold processing, plastic molding, aerospace, etc. In these scenarios, the mold temperature machine is one of the indispensable and important equipment.

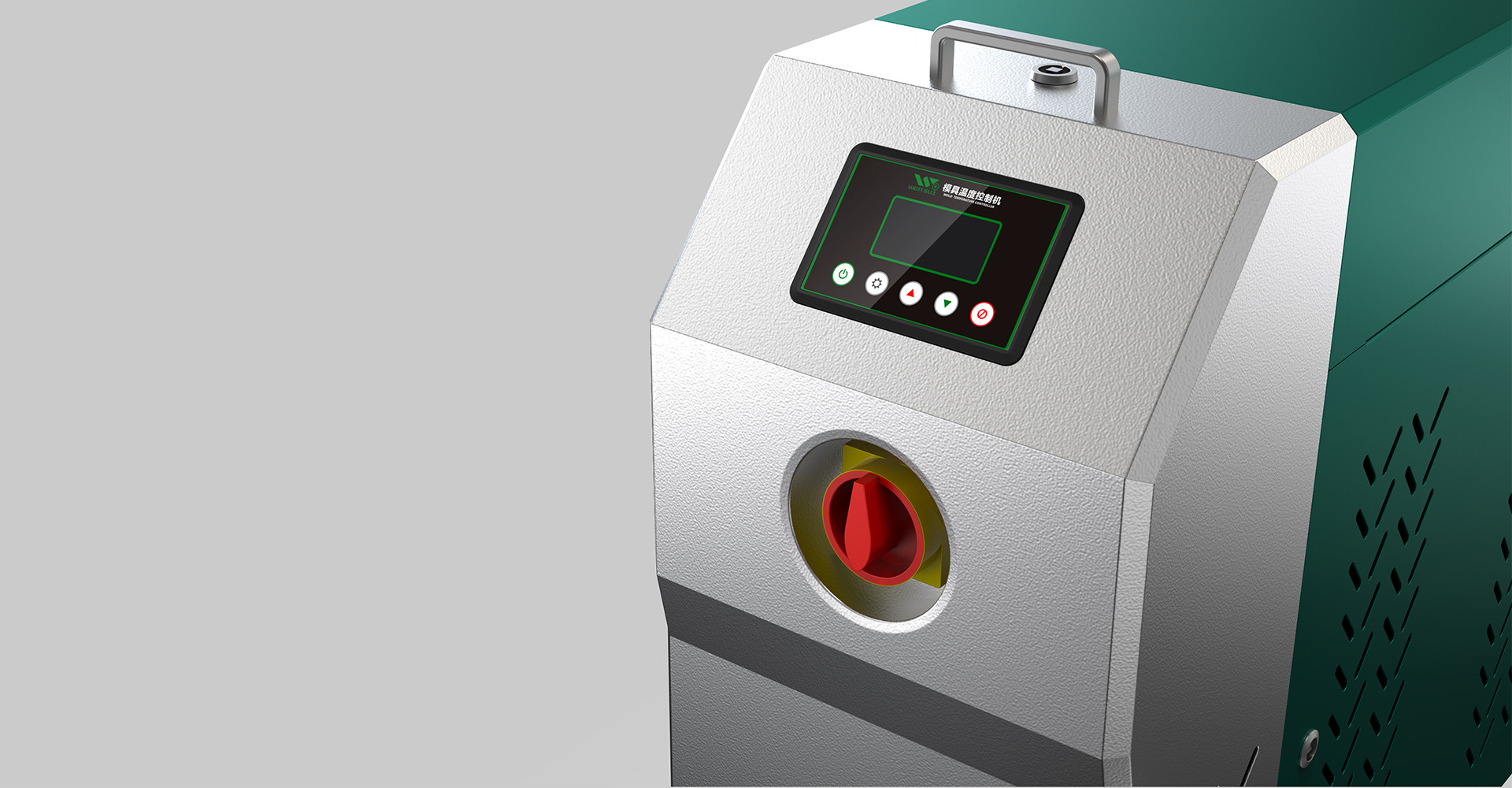

Mold temperature machine is a widely used equipment in the industrial field, which can provide precise temperature control for molds, thereby improving production efficiency and quality. The design concept of this mold heater emphasizes practicality and ease of use. In terms of appearance design, we have adopted a simple and elegant design style, paired with modern color matching, which is not only beautiful and elegant, but also easy to integrate with the production workshop. In order to facilitate user operation, we have designed an easy-to-use user interface. Clear identification and easy to operate layout allow users to have a clear understanding of the functions of each button. The high-definition digital display screen can display real-time information such as device temperature and operating status.

We participated in the industrial design of the mold temperature control machine and understood the customer's company philosophy based on the target market and customer needs. In terms of design, the element of "wheat ears" is taken and simplified by extracting elements, simplifying the heat dissipation hole into an upward growing wheat ear, symbolizing the longing and hope for a better life. Use green to color segment the product, making it visually more cohesive and atmospheric. In terms of materials, we have adopted corrosion-resistant and wear-resistant materials to ensure that the equipment remains aesthetically pleasing and practical even after prolonged use.

In terms of materials, we have chosen stainless steel plates and cold-rolled plates. Stainless steel plates have the advantages of heat resistance and low temperature resistance, as well as good corrosion resistance and are not easily deformed. In terms of appearance, they not only enrich the product appearance, but also reflect the industrial style of the equipment. Cold rolled sheet has good performance, with precise dimensions, uniform thickness, high flatness, and high surface smoothness. At the same time, it has the characteristics of high stamping performance, non aging, and low yield point.

On the basis of in-depth exploration of user needs and market trends, this design has finally been completed. We hope that through this design, we can bring users a brand new experience that not only meets their needs, but also exceeds their expectations. Our team always adheres to the concept of "following the trend, creating designs that convey warmth and touch people's hearts". Through continuous experimentation and improvement, we strive to make every detail full of humanization and practicality. We are well aware that a successful product requires not only a beautiful appearance, but also a rich connotation and perfect functionality. Although the design work has come to an end, our exploration and innovation of the product will never stop. I look forward to continuously improving and optimizing this product in the future to better serve users and bring more valuable products and services to them.